A perfect solution for waste disposal

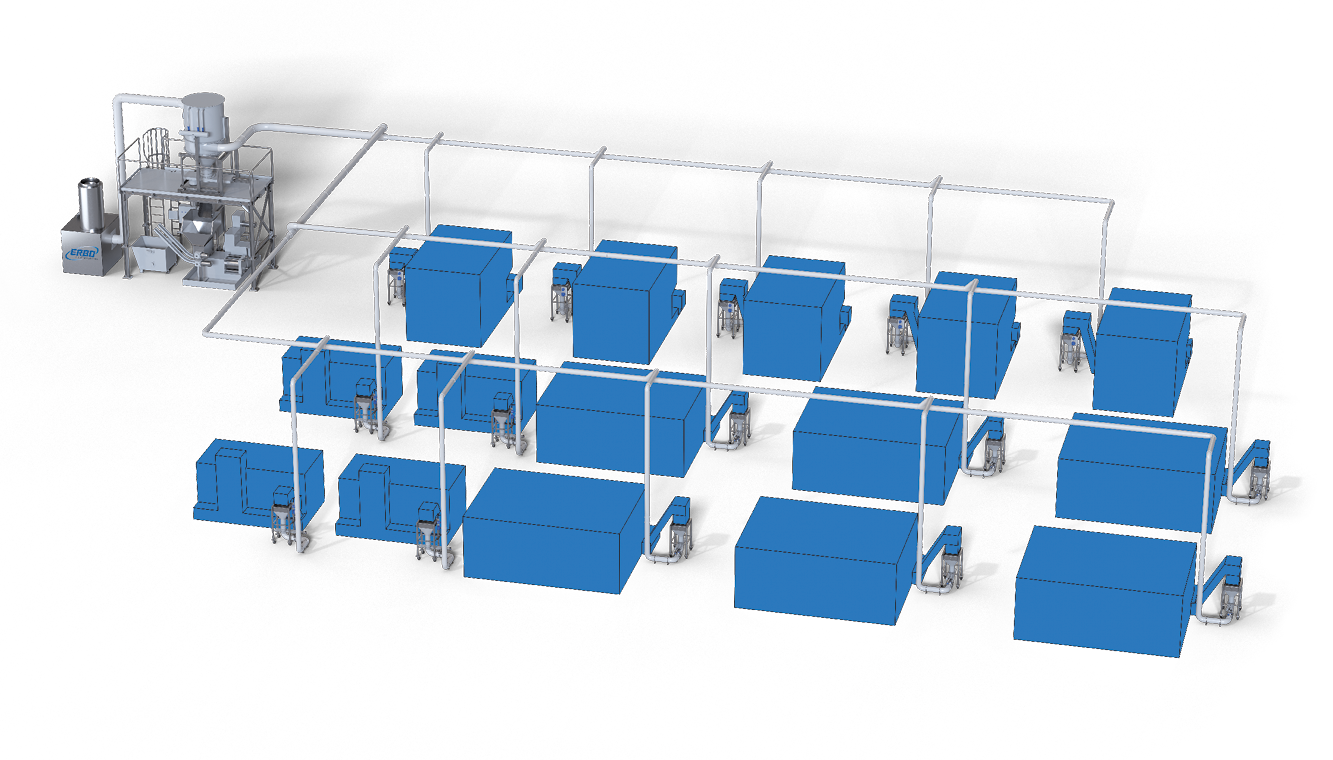

Our extraction systems capture the chips directly at the chip conveyor of your CNC milling machines and move them automatically to a central location away from the production floor. This does away with the burdensome task of moving the small containers within the company and tipping them into the large container, and creates more space around the machines.

Laborious transport a thing of the past

The central extraction system can dump the chips directly into a large container or feed them into a briquetting press, for example – this can be decided based on the local requirements. As a rule, it does not matter whether the chips are long or short, wet or dry: our extraction equipment, in combination with downstream crushing or shredding equipment if desired, provides the greatest possible flexibility.

Your benefits

- No in-house transports of small containers

- No emptying of small containers into large container

- Saving space around the machines

- Fully automated disposal of chips even over long distances

- Closed and fully automated chip handling cycle

- Alloy separation and/or separation of metal and aluminum chips

- Briquetting achieves volume reduction

- Briquetting produces dry chips

- Flexible system with modular extensions

Our central extraction system makes it possible to automatically separate alloys in aluminum chips, or to automatically separate metal and aluminum chips. We design, deliver, and assemble fully automated end-to-end systems for your company including chip conveyors, crushing or shredding equipment, briquetting systems, and chip centrifuges for every type of chips: a perfect solution that saves space, simplifies handling and adds value.

Tailor-made automated solutions for:

- Alloy separation

- Central extraction systems

- Briquetting

- Cooling lubricant recovery

- Automated chip handling

- Shredding or crushing

- Vibratory conveyors

- Chip conveyors