MORE THAN JUST EXTRACTION

As a solid family business with more than 40 years of experience in the machining industry and chip processing, we plan, develop and install innovative extraction systems appreciated by customers all over the world. More about us

Our offerings for you

With know-how and foresight, we are your partner for tailor-made custom systems. Right from the start, we focus on the safe, reliable and efficient process flow in your company. Whether you’re a small business or a global corporation – with ERBO you enjoy an excellent service including detailed on-site analysis, development of a system tailored to your business, comprehensive project management and rapid troubleshooting when needed. In 2023, the reputable DELTOID products were folded into our portfolio.

As a specialist for tailor-made systems engineering, we enjoy global success.

Our customers

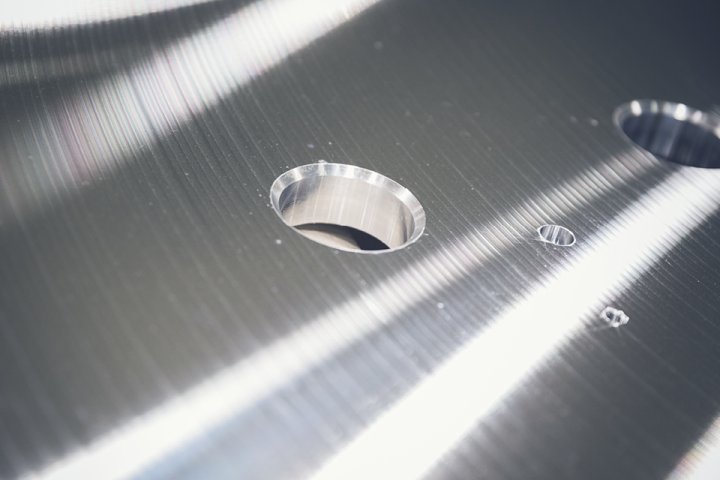

Wherever manufacturing processes produce chips, ERBO systems are in demand We offer solutions for different materials. ERBO does more than just extract the chips: our innovative technology turns scrap into valuable raw materials.

Automatic extraction and chip processing for CNC milling machines

At alimex, an ERBO system converts waste chips back into a valuable raw material during the production process. Click here to read this ‘chipping’ story. LEARN MORE