HIGH EXTRACTION PERFORMANCE – HIGH QUALITY

As specialists for systems in circuit board manufacturing, we are well aware from many years of experience of the demands, challenges and risks involved in this industry. In highly sensitive production industries such as the manufacturing and processing of circuit boards, there are many factors that cause uncertainty. Thus every fixed parameter – such as constant, powerful extraction, for example – represents a genuine quality gain for your company.

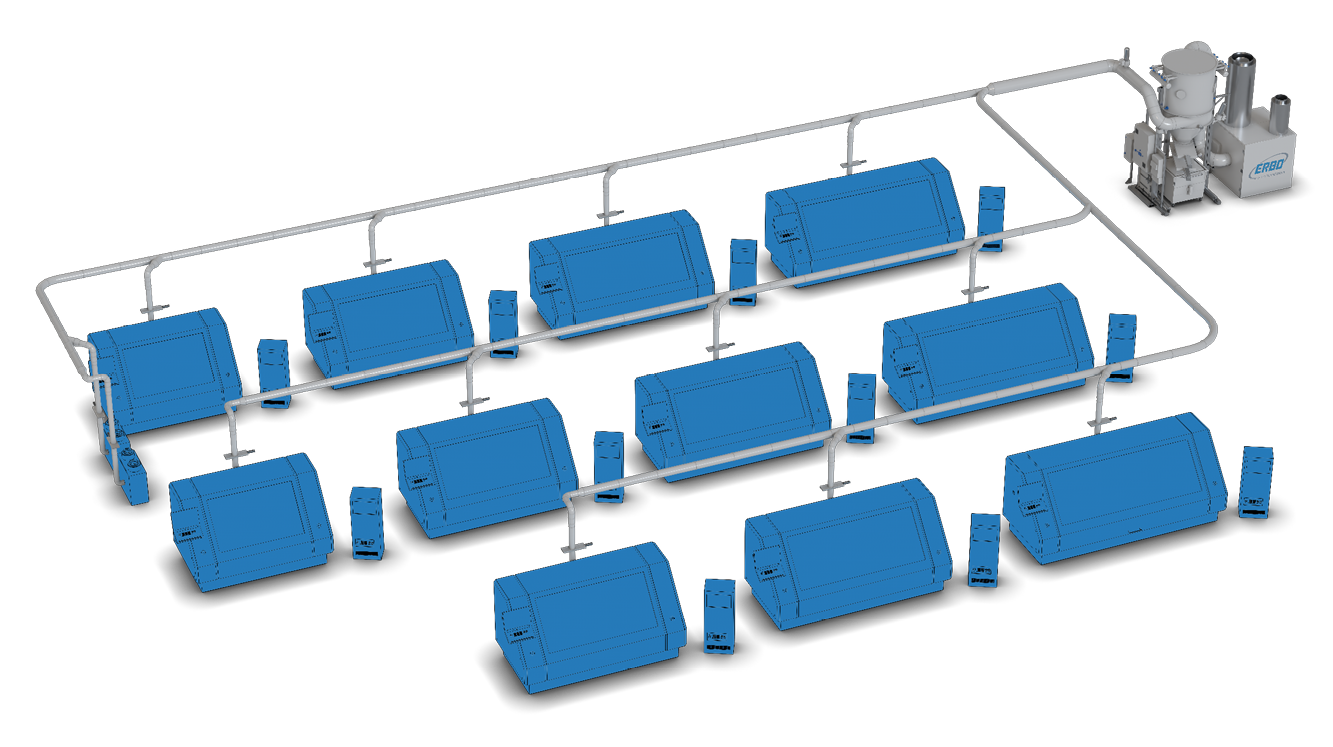

We build central extraction systems for:

- Drilling and milling machines

- Scoring machines

- Edge processing machines

- Panel saws

- Laser drilling machines

- Laser machining centres

- Depanelling machines

Say goodbye to machine downtime!

Without optimal extraction for the machines, dust particles on the boards, in the milled grooves and in the tiny drill holes will impair the quality of your circuit boards. ERBO extraction systems are fully automated and reliable, making unplanned downtime of drilling and milling machines a thing of the past. We deliver our systems worldwide in a wide range of sizes: from systems with 2–10 spindles for smaller operations to extraction systems with 20 or even several hundred spindles.